durable projector fabric design for projector screen1

Model:

WG1 Pro

Original:

Guangzhou,China

MOQ:

1 roll

Delivery Time:

5~10 working days

Trade Terms:

EXW, FOB Guangzhou, CIF, Door to door.

Payment Terms:

T/T, Western Union, PayPal, L/C

Packing:

Plywood Case

Shipping:

By sea, By air

Certificate:

UL,CE, ROHS, ISO 9001

Warranty:

12 months

Max Width:

2.2m

Company Advantages

1. The production environment of XY Screens best material to use for projector screen is required to be neat, clean, noise and dust free. Workers are required to wear dust suit in the work plant. XY projection screen features a warm and elegant look

2. Whether one wants to magnify a gaming adventure, splash a movie across a massive white wall in the evening with family or have slides or photographs from the mobile device to a 100-inch plus screen, this product should be the top pick. XY projection screen can maintain a perfectly smooth image

3. The product features small friction power consumption. Due to the small contact area for the friction pair, combining with semi-fluid lubrication or boundary lubrication, the friction power is very small. Special Motor in roller design keeps the screen in quiet and smooth operation

Company Features

1. The company has got the export license years ago. With this license, we have availed benefits in the form of subsidies from the Customs and Export Promotion Council authorities. This has promoted us to win over the market by offering price-competitive products.

2. Under the concept of win-win cooperation, we are working to seek long term partnerships. We unwaveringly refuse to sacrifice product quality and customers' service.

1. The production environment of XY Screens best material to use for projector screen is required to be neat, clean, noise and dust free. Workers are required to wear dust suit in the work plant. XY projection screen features a warm and elegant look

2. Whether one wants to magnify a gaming adventure, splash a movie across a massive white wall in the evening with family or have slides or photographs from the mobile device to a 100-inch plus screen, this product should be the top pick. XY projection screen can maintain a perfectly smooth image

3. The product features small friction power consumption. Due to the small contact area for the friction pair, combining with semi-fluid lubrication or boundary lubrication, the friction power is very small. Special Motor in roller design keeps the screen in quiet and smooth operation

Fabric Parameter

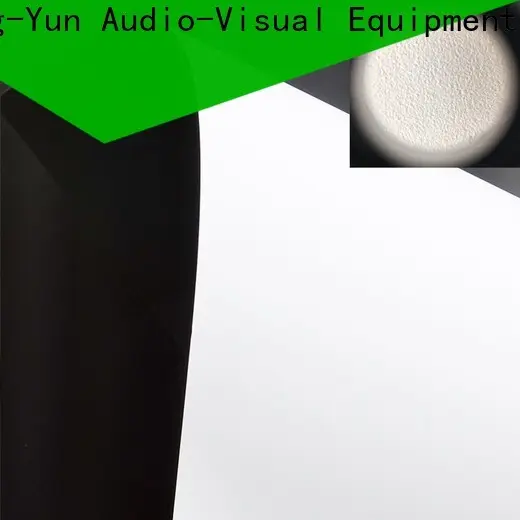

| Model Name: | WG1 Pro | Color: | Front: white Back: black |

| Material: | PVC fabric+ fiberglass+ coating | Moisture Resistant: | Yes |

| Gain: | 1.1 | Cleanable: | Yes |

| Viewing Angle: | 160 degree | Roll Width: | 2.2m |

| Hole Diameter: | / | Application: | Advanced, Top theater |

| Thickness: | 0.32 mm | Fabric Feature: | Smooth surface, excellent effect |

| Available Products: | Motorized Projection Screen | ||

Description:

WG1 Pro uses basic three-layer structure. The outer layer is white coating; middle layer is glass fibre; inner layer is black layer. Made of glass fibre, the screen must be very smooth. WG1 Pro is a diffusion screen and its surface has fine and smooth lines, providing the best visual angle and excellent color rendition.

Company Features

1. The company has got the export license years ago. With this license, we have availed benefits in the form of subsidies from the Customs and Export Promotion Council authorities. This has promoted us to win over the market by offering price-competitive products.

2. Under the concept of win-win cooperation, we are working to seek long term partnerships. We unwaveringly refuse to sacrifice product quality and customers' service.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Contact us

we welcome custom designs and ideas and is able to cater to the specific requirements. for more information, please visit the website or contact us directly with questions or inquiries.

you might like

no data

Professional in producing projection screens over 10 years

Contact Information

- Tel: +86-20-39133522

- Fax: +86-20-39133523

- Email: info@xy-screen.com

- 24-hour hotline: +86-20-39133522

- Address: Floor 1, Tianyi Technology Park, No.110, Lanbei Road, Lanhe Town, Nansha District, Guangzhou, Guangdong Province, China, 511400