normal Ambient Light Rejecting Fabrics customized for motorized projection screen

Model:

PET Crystal

Original:

Guangzhou,China

Payment Terms:

T/T, Western Union, PayPal, L/C

Packing:

Standard Export Cartons

Shipping:

By sea, By air or By express delivery (DHL/UPS/FEDEX/TNT)

Warranty:

12 months

Company Advantages

1. XY Screens matte white fabric for projection screen is a well-manufactured outcome by developers, designers, production workers, QC team, etc. It has to be constantly inspected, maintained, and upgraded in terms of its electric components. Large diameter rollers ensure long-term screen integrity providing a consistent flat projection surface

2. The use of this product in commercial building designs will become an enduring trend for many aesthetic and energy efficiency reasons. Our strength lies in sophisticated manufacturing and in-house design unit that help us in offering vast range and specifications to our clients

3. This product has electromagnetic compatibility. Techniques and technologies for reducing disturbance and enhancing immunity are cleverly used in its manufacturing. XY projection screen provides excellent value for money

Company Features

1. Our project management team is highly qualified. They learn well about manufacturing practices and are offered with years of expertise, which helps meet the manufacturing needs of our customers.

2. Guangzhou Xiong-Yun Audio-visual Equipment Co., Ltd. makes a firm commitment to our customers, we will always provide the high quality Ambient Light Rejecting Fabrics . Please contact.

1. XY Screens matte white fabric for projection screen is a well-manufactured outcome by developers, designers, production workers, QC team, etc. It has to be constantly inspected, maintained, and upgraded in terms of its electric components. Large diameter rollers ensure long-term screen integrity providing a consistent flat projection surface

2. The use of this product in commercial building designs will become an enduring trend for many aesthetic and energy efficiency reasons. Our strength lies in sophisticated manufacturing and in-house design unit that help us in offering vast range and specifications to our clients

3. This product has electromagnetic compatibility. Techniques and technologies for reducing disturbance and enhancing immunity are cleverly used in its manufacturing. XY projection screen provides excellent value for money

Fabric Parameter

| Model Name: | PET Crystal | Color: | Front: dark grey Back: black |

| Material: | PET fabric+light resistant coating | Moisture Resistant: | Yes |

| Gain: | 0.8 | Cleanable: | Yes |

| Viewing Angle: | 160 degree | Roll Width: | / |

| Hole Diameter: | / | Application: | Advanced, Top theater |

| Thickness: | 0.49 mm | Fabric Feature: | Ultra-short throw, Ambient light rejection |

| Available Products: | Ultra Thin Frame Projection Screen, Hard Projection Screen | ||

Description:

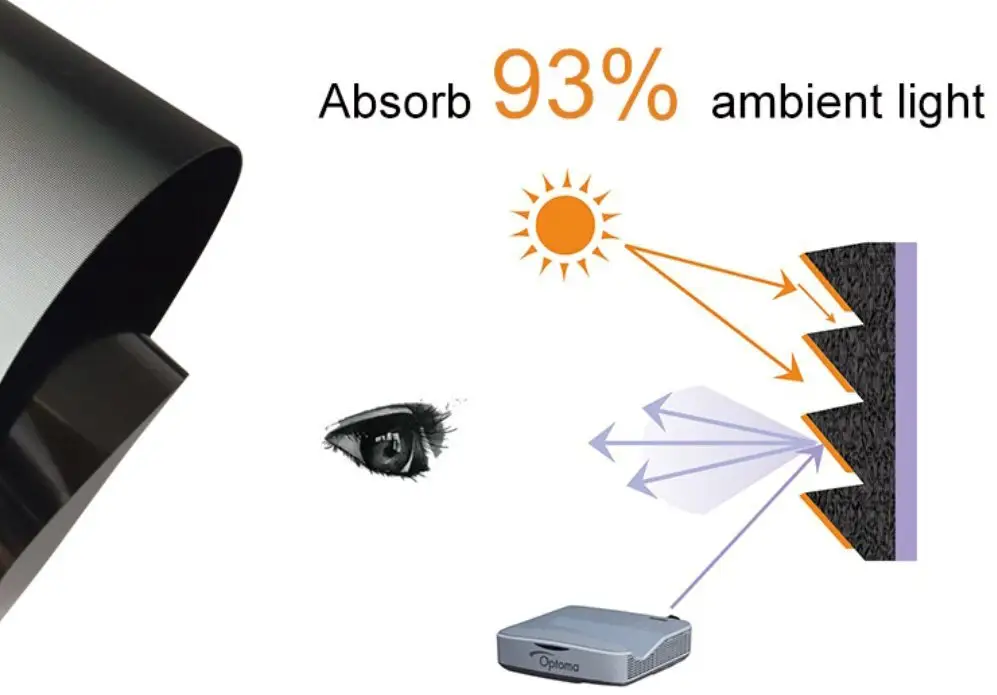

With special optical sawtooth structure, the ultrashort anti-light screen PET Crystal can avoid 93% ambient light, to present real color. Also, it has no light reflection. Unlike traditional projection screen, PET Crystal is able to present image under bright light. It has removed foggy phenomenon, providing bright, vivid and perfect pictures. With Gain of 0.8 and viewing angle of 160 degree, the audience can see clear and vivid image in all directions. Even if you have watched for a long time, your eyes will not feel tired. Compared to traditional matte white screen, its contrast has been lifted by 10 times.

Company Features

1. Our project management team is highly qualified. They learn well about manufacturing practices and are offered with years of expertise, which helps meet the manufacturing needs of our customers.

2. Guangzhou Xiong-Yun Audio-visual Equipment Co., Ltd. makes a firm commitment to our customers, we will always provide the high quality Ambient Light Rejecting Fabrics . Please contact.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Contact us

we welcome custom designs and ideas and is able to cater to the specific requirements. for more information, please visit the website or contact us directly with questions or inquiries.

you might like

no data

Professional in producing projection screens over 10 years

Contact Information

- Tel: +86-20-39133522

- Fax: +86-20-39133523

- Email: info@xy-screen.com

- 24-hour hotline: +86-20-39133522

- Address: Floor 1, Tianyi Technology Park, No.110, Lanbei Road, Lanhe Town, Nansha District, Guangzhou, Guangdong Province, China, 511400