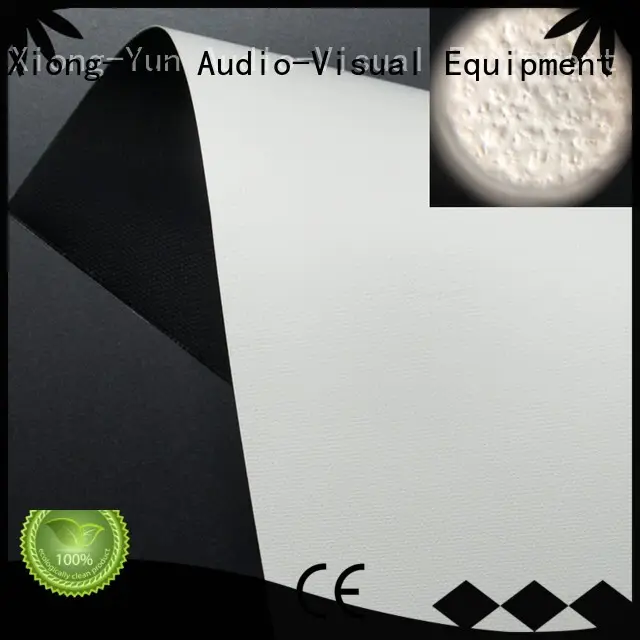

professional front and rear fabric design for projector screen

Model:

WG1

Original:

Guangzhou,China

MOQ:

1 roll

Delivery Time:

5~10 working days

Trade Terms:

EXW, FOB Guangzhou, CIF, Door to door.

Payment Terms:

T/T, Western Union, PayPal, L/C

Packing:

Plywood Case

Shipping:

By sea, By air

Certificate:

UL,CE, ROHS, ISO 9001

Warranty:

12 months

Max Width:

3.2m

Company Advantages

1. Innovation-oriented design: XY Screens black projector screen material is innovatively designed by a team of professional designers. They are full of innovative ideas and are willing to embrace the changing market demands. Our strength lies in sophisticated manufacturing and in-house design unit that help us in offering vast range and specifications to our clients

2. It reinforces the brand image. Investing in this product extends marketing and branding activities while leaving an impression on every aspect of the distribution chain. A wide range of Projector Screen is made available, which has been designed using modern technology to impart several beneficial features

3. The product has a long operation life and can be held up for a long time. Thus, it is proved that this quality product has won high recognition in the market for its durability. XY projection screens are available in a wide range of sizes and prices

4. Its quality is guaranteed as its quality testing tends to be more rigorous and controlled based on the international standards instead of the national rules. For those wanting an amazingly flat surface, tensioned versions are also available

5. Our quality management system ensures that the product meets with the international quality standards. Our products are popular in the overseas market

Company Features

1. With its cutting-edge scientific research capabilities, Guangzhou Xiong-Yun Audio-visual Equipment Co., Ltd. has become a professional supplier of front and rear fabric products. Our company wins the acclaim all over the world with strong first-class products, high-quality goods, rapid and timely delivery, pre-sales value-added service.

2. Our company houses a pool of candidates who are highly qualified in customer services. They have gone through professional training and are able to provide advice and are skillful in managing the negative emotion of customers.

3. The company is endowed with an excellent product management team. They often come up with effective selling solutions by working together and brainstorming ideas. With the purpose of reducing the impact of our products on the environment, we make changes in our production. We are committed to developing products with higher recyclability and renovate our packaging ways.

1. Innovation-oriented design: XY Screens black projector screen material is innovatively designed by a team of professional designers. They are full of innovative ideas and are willing to embrace the changing market demands. Our strength lies in sophisticated manufacturing and in-house design unit that help us in offering vast range and specifications to our clients

2. It reinforces the brand image. Investing in this product extends marketing and branding activities while leaving an impression on every aspect of the distribution chain. A wide range of Projector Screen is made available, which has been designed using modern technology to impart several beneficial features

3. The product has a long operation life and can be held up for a long time. Thus, it is proved that this quality product has won high recognition in the market for its durability. XY projection screens are available in a wide range of sizes and prices

4. Its quality is guaranteed as its quality testing tends to be more rigorous and controlled based on the international standards instead of the national rules. For those wanting an amazingly flat surface, tensioned versions are also available

5. Our quality management system ensures that the product meets with the international quality standards. Our products are popular in the overseas market

Fabric Parameter

| Model Name: | WG1 | Color: | Front: white Back: black |

| Material: | PVC fabric+ fiberglass+ coating | Moisture Resistant: | Yes |

| Gain: | 1.0 | Cleanable: | Yes |

| Viewing Angle: | 160 degree | Roll Width: | 3.2m |

| Hole Diameter: | / | Application: | Entry level, intermediate theater |

| Thickness: | 0.4 mm | Fabric Feature: | Smooth surface, excellent effect |

| Available Products: | Motorized Projection Screen | ||

Description:

WG1 is made of fiberglass. Its surface is coated with special PVC. Its unique coating technology provides you incomparable experience. The projected image becomes more vivid and natural.

Company Features

1. With its cutting-edge scientific research capabilities, Guangzhou Xiong-Yun Audio-visual Equipment Co., Ltd. has become a professional supplier of front and rear fabric products. Our company wins the acclaim all over the world with strong first-class products, high-quality goods, rapid and timely delivery, pre-sales value-added service.

2. Our company houses a pool of candidates who are highly qualified in customer services. They have gone through professional training and are able to provide advice and are skillful in managing the negative emotion of customers.

3. The company is endowed with an excellent product management team. They often come up with effective selling solutions by working together and brainstorming ideas. With the purpose of reducing the impact of our products on the environment, we make changes in our production. We are committed to developing products with higher recyclability and renovate our packaging ways.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Contact us

we welcome custom designs and ideas and is able to cater to the specific requirements. for more information, please visit the website or contact us directly with questions or inquiries.

you might like

no data

Professional in producing projection screens over 10 years

Contact Information

- Tel: +86-20-39133522

- Fax: +86-20-39133523

- Email: info@xy-screen.com

- 24-hour hotline: +86-20-39133522

- Address: Floor 1, Tianyi Technology Park, No.110, Lanbei Road, Lanhe Town, Nansha District, Guangzhou, Guangdong Province, China, 511400