thin curved projector screen diy manufacturer for theater

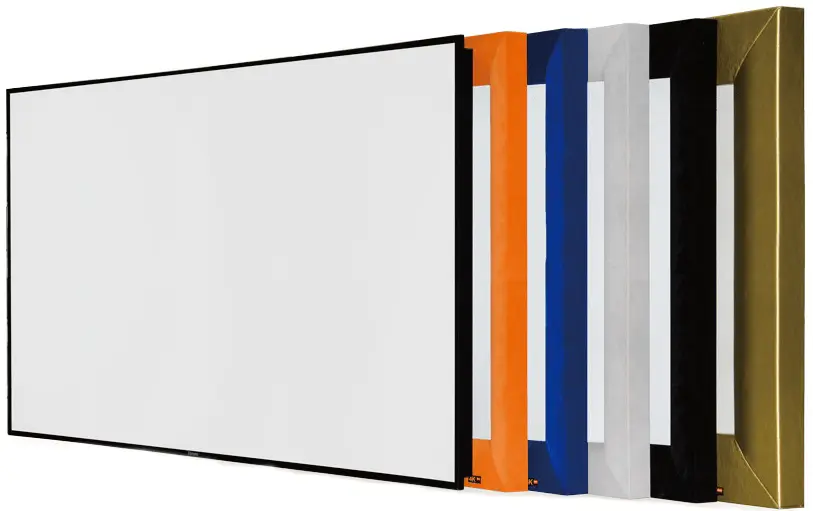

Curved Frame Projection Screen CHK100C Series

◆◆ Product Description

XY Screens Curved Fixed Frame Projector Screen adds a flare of style and ambiance to any Home Theater or Auditorium application. Creating the effect of enveloping the audience with its curved corners, the screen wraps the viewer in a full panoramic experience. The CHK Series Curved Frame projector screen design enhances the aesthetic appeal, while also optimizing light reflectivity towards the audience.

Compared to flat screen, curved screen can do larger size in the same space, for example, in a 128 inch wide space, the maximum of flat screen is only do 128 inch wide, but the curved screen can do 130 inch wide.

We offer various types of screen surfaces to suit your viewing environment. Different surfaces are available for different frames:

CHK100C - WF1, GF1, WF1 Pro, WFS1, WF1 Pro Max4K HG, Black Crystal, Sound Max2, Sound Max4K, RGF1, MF1, MFS1.

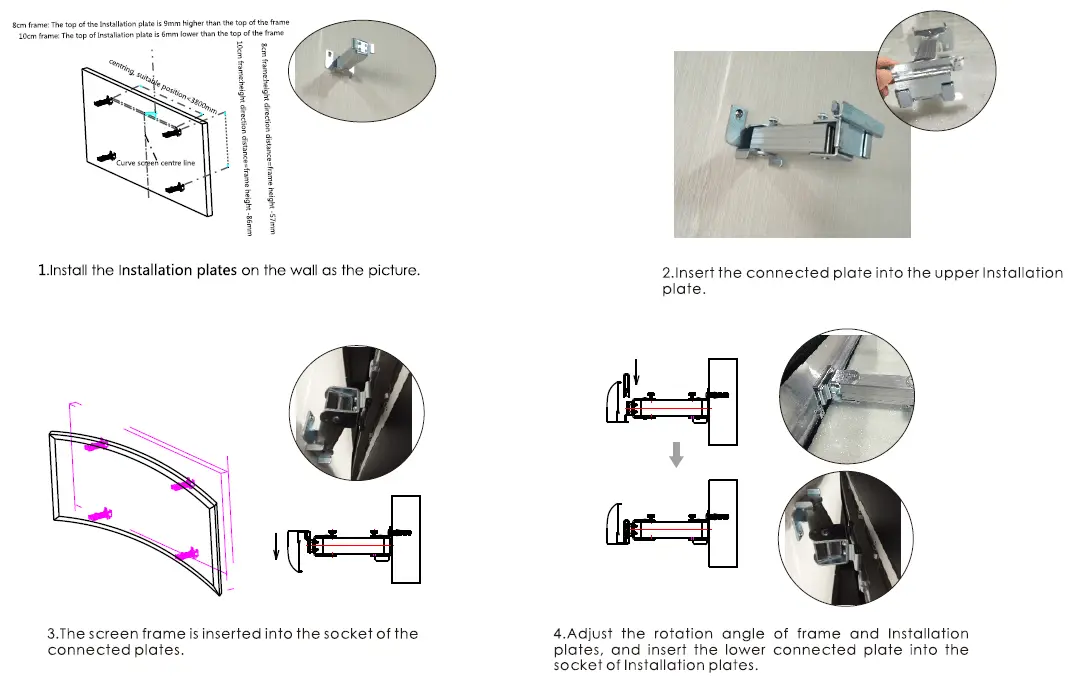

Installation is easy - With its easy and adjustable fabric spring system, our Fixed Frame Screen is perfectly and permanently tensioned, the users are able to set up in seconds.

Flexible adjustment - Screen could slide along the specially designed brackets to achieve a best view position, also available as an in-wall display.

◆◆ Product Specification

| Frame Material: | Aluminum Alloy |

| Housing Color: | Black / White / Grey / Orange / Blue / Golden Velvet |

| Size: | 80-300 inch / customized |

| Aspect Ratio: | 16:9 / 16:10 / 4:3 / 1:1 / 2.35:1 / customized |

| Frame Width: | 100mm |

| HD: | Yes |

| 3D: | Yes |

| 4K: | Different fabrics are optional |

| Bend Radius: | Minimum is 0.75 times of standard bend radius; Maximum is 2 times of standard bend radius. |

◆◆ Product Features

◆ Four Sided Tension Design - Spring System

The tension springs along with the fixing lugs stretching and tightening the fabric to make the screen surface completely flat and wrinkle-free

High quality aluminum alloy frame wrapped in velvet.

Corner brace

100mm width aluminum alloy frame

Elegant appearance

Stable and easy hook system

Bottom Mouting Bracket

◆ In order to facilitate transport, horizontal frame of 120"+ will be jointed by two or three pieces to reduce the total length

1. Top Bracket 2. Bottom Bracket 3. Corner Brace 4. Connecting Bar

5. Screwdriver 6. Hook(To install the springs) 7. Spring 8. Flexible Mouting Bracket

Product Model | Fabric Model | HD/4K | Support 3D Mode | Sound-Transparent |

|---|---|---|---|---|

| CHK100C-WF1 | WF1 | HD | Active | No |

| CHK100C-GF1 | GF1 | HD | Active | No |

| CHK100C-WF1 Pro | WF1 Pro | 4K | Active | No |

| CHK100C-FS1 | FS1 | 4K | Active | Yes |

| CHK100C-WF1 Pro Max4K HG | WF1 Pro Max4K HG | 4K | Active | No |

| CHK100C-Black Crystal | Black Crystal | 4K | Active | No |

| CHK100C-Sound Max2 | Sound Max2 | 4K | Active | Yes |

| CHK100C-Sound Max4K | Sound Max4K | 4K | Active | Yes |

| CHK100C-RGF1 | RGF1 | HD | Active | No |

| CHK100C-MF1 | MF1 | 4K | Active + Passive | No |

| CHK100C-MFS1 | MFS1 | 4K | Active + Passive | Yes |

Supporting Customized Size

Size From 80" to 300" are available in any ratio

Professional in producing projection screens over 10 years

Contact Information

- Tel: +86-20-39133522

- Fax: +86-20-39133523

- Email: info@xy-screen.com

- 24-hour hotline: +86-20-39133522

- Address: Floor 1, Tianyi Technology Park, No.110, Lanbei Road, Lanhe Town, Nansha District, Guangzhou, Guangdong Province, China, 511400