transparent 120 acoustically transparent screen directly sale for thin frame projector screen

Model:

MFS1

Original:

Guangzhou,China

MOQ:

1 roll

Delivery Time:

5~10 working days

Trade Terms:

EXW, FOB Guangzhou, CIF, Door to door.

Payment Terms:

T/T, Western Union, PayPal, L/C

Packing:

Plywood Case

Shipping:

By sea, By air

Certificate:

UL,CE, ROHS, ISO 9001

Warranty:

12 months

Max Width:

3.66m-6m

Aluminum metal shell

16:9 / 4:3/customized

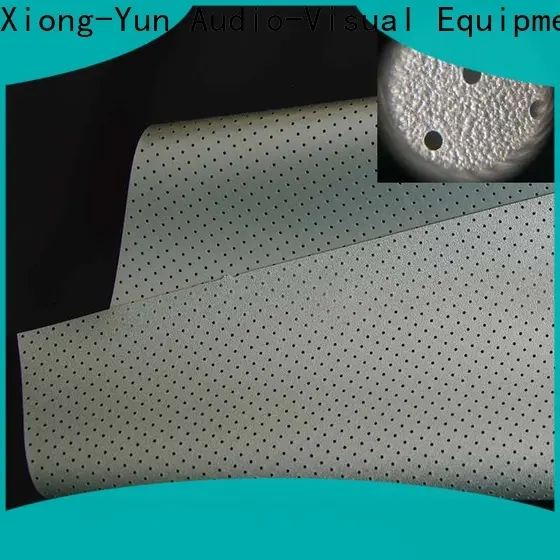

Fabric Parameter

| Model Name: | MFS1 | Color: | Front: silver Back: silver |

| Material: | Soft PVC +Coating | Moisture Resistant: | Yes |

| Gain: | 2.0 | Cleanable: | Yes |

| Viewing Angle: | 120 degree | Roll Width: | 3.66m - 6m |

| Hole Diameter: | 0.6 mm | Application: | Cinema, large project, clubs |

| Thickness: | 0.4 mm | Fabric Feature: | Acoustic transparent, High Gain |

| Available Products: | Ultra Thin Frame Projection Screen, Fixed Frame Projection Screen, Motorized Projection Screen | ||

Description:

MFS1 is coated with high-reflective metal mixed polyvinyl resin, providing high Gain and clear image. In particular, it is vivid and natural when presenting dynamic video or pictures. It is suitable to show movie, 3D automation and computer game. Also, it is suitable for different types of theaters, classrooms, meeting rooms and command posts.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Contact us

we welcome custom designs and ideas and is able to cater to the specific requirements. for more information, please visit the website or contact us directly with questions or inquiries.

you might like

no data

Professional in producing projection screens over 10 years

Contact Information

- Tel: +86-20-39133522

- Fax: +86-20-39133523

- Email: info@xy-screen.com

- 24-hour hotline: +86-20-39133522

- Address: Floor 1, Tianyi Technology Park, No.110, Lanbei Road, Lanhe Town, Nansha District, Guangzhou, Guangdong Province, China, 511400