Professional in producing projection screens over 11 years

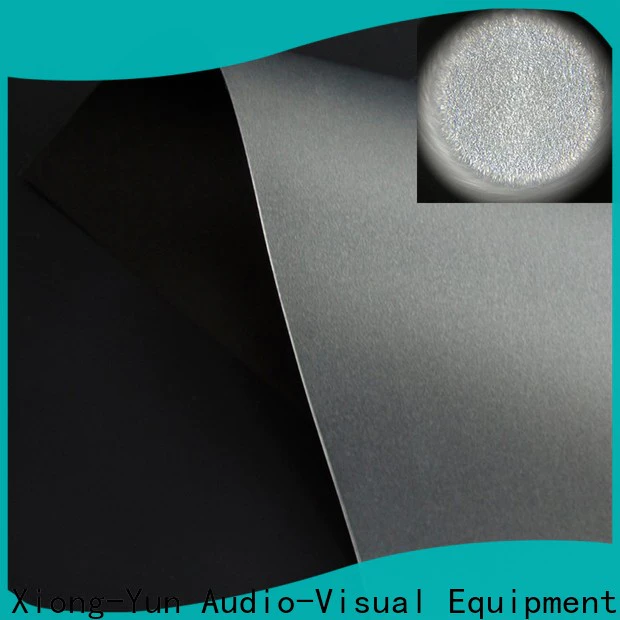

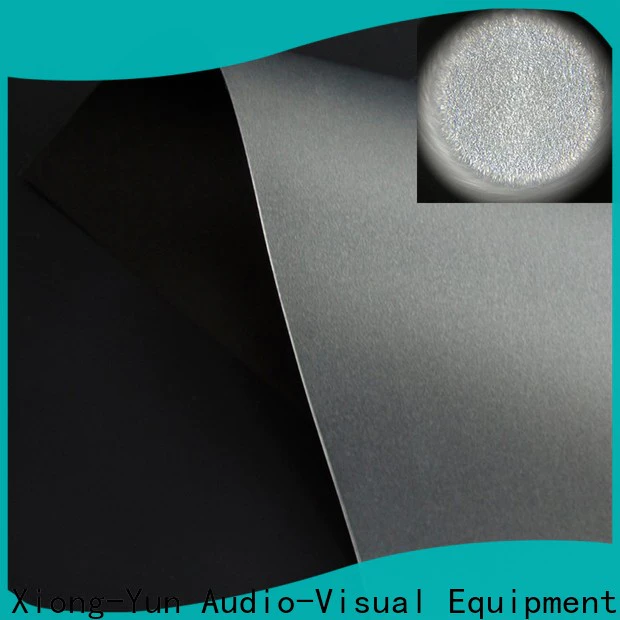

| Model Name: | Black Crystal HG | Color: | Front: grey Back: black |

| Material: | PET fabric+black crystal coating | Moisture Resistant: | Yes |

| Gain: | 1.8 | Cleanable: | Yes |

| Viewing Angle: | 90 degree | Roll Width: | 2.5m |

| Hole Diameter: | / | Application: | Advanced, Top theater |

| Thickness: | 0.35 mm | Fabric Feature: | Normal throw, Ambient light rejection, High Gain |

| Available Products: | Ultra Thin Frame Projection Screen, Fixed Frame Projection Screen, Hard Projection Screen | ||

Description:

Black Crystal HG is made of PET, specially developed for environment with ambient light. It is for normal throw projectors. The surface is covered with special ambient light rejecting material. In the bright environment, this screen can still show first-class quality, the color is quite brilliant.

Copyright © 2019 Guangzhou Xiong-Yun Audio-Visual Equipment Co., Ltd. | All Rights Reserved 粤ICP备13065530号

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.