Company Advantages1. XY Screens cheap projector screen material has to be tested. It is carefully measured in terms of insole length, insole width, toe lift, heel height and back height for proper fitting, symmetry and sizing requirements. Our products are well received in China, the United States, Europe, the Philippines, Indonesia and other countries

2. People find that this product is extremely flexible and durable, making it ideal for many applications such as car manufacturing. XY projection screen is ideal for applications where a recessed installation is not desired or feasible

3. The performance of Ambient Light Rejecting Fabrics is almost the same as overseas similar product performance. The aluminum alloy case is stylish and durable, available in white color

4. This product has a long service life while delivering constantly high quality. XY projection screens are available in a wide range of sizes and prices

Model

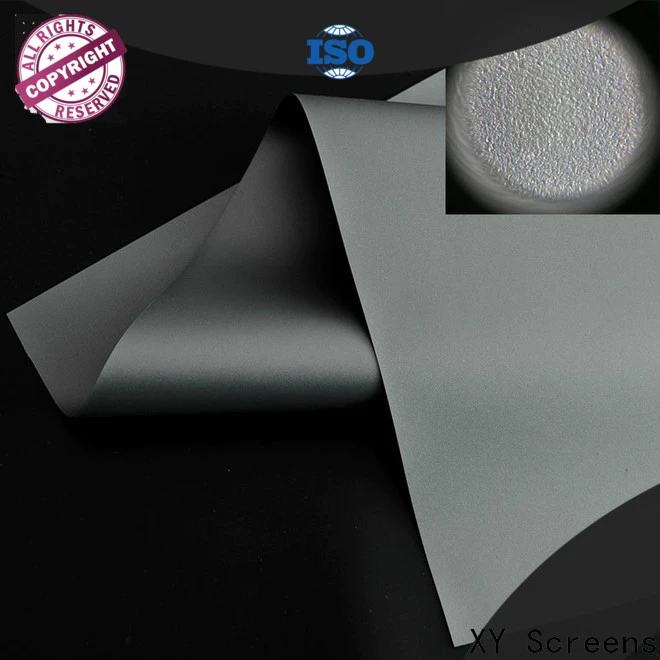

Name: | Black Crystal | Color: | Front: dark grey

Back: silver |

| Material: | PVC fabric+black crystal coating | Moisture

Resistant: | Yes |

| Gain: | 0.8

| 3D: | Active 3D |

Viewing

Angle: | 160 degree | Roll

Width: | 2.5m / 3.2m |

| 4K: | YES | Application: | Advanced, Top theater |

| Thickness: | 0.31 mm | Fabric

Feature: | Normal throw, Ambient light rejection, Low Gain |

Available

Products: | Ultra Thin Frame Projection Screen, Fixed Frame Projection Screen, Motorized Projection Screen, Fast Fold Projection Screen |

Description:

Black Crystal is made of PVC, which is coated with special anti-light material, which absorbs ambient light and lamplight. This product has great anti-interference feature. There is a layer of crystal in the middle of the surface, which effectively improve the brightness and contrast.

Company Features1. Guangzhou Xiong-Yun Audio-visual Equipment Co., Ltd. is a mainstay Chinese enterprise of Ambient Light Rejecting Fabrics . The factory is located near the main road and highways. This convenient transportation has brought us more opportunities and competitive advantages in both domestic and foreign markets.

2. Our current customers are mainly in the European and USA markets. We have got good word of mouth due to our high-quality products and innovative designs.

3. The strong R&D team is a power to promote our growth. They all have excellent educational backgrounds. With knowledge and deep industry know-how, they are always able to offer customers satisfying product solutions. We believe in sustainable development by ensuring that all our production activities are in harmony with the environment. We will adopt high efficient facilities and testing equipment to control and minimize the impact of waste and emission during production.